How Leading Manufacturers Ensure Consistent Production of Cannabis Vapes

In the rapidly evolving cannabis industry, consistent vape product quality is crucial for brand reputation, consumer safety, and regulatory compliance. With industry leaders like Transpring constantly setting the standard, understanding the complex processes and strategies behind consistent cannabis vape production is crucial. This guide comprehensively explores the key methods, technological innovations, and quality assurance protocols employed by leading manufacturers to ensure product consistency, safety, and high performance.

The Criticality of Consistency in Cannabis Vape Production

Consistency in cannabis vape products is the cornerstone of quality, encompassing aspects such as flavor, potency, vapor volume, battery reliability, and overall safety standards. Variations in any of these factors can negatively impact the consumer experience, leading to dissatisfaction, decreased trust, brand damage, and even increased regulatory scrutiny.

Forward-thinking manufacturers understand that standardization goes beyond compliance; it's about delivering a reliable and enjoyable experience every time. By maintaining strict quality control and consistency throughout all stages of production, brands can build consumer confidence, encourage repeat purchases, and foster long-term loyalty. This commitment to reliability not only safeguards the company's reputation but also allows leaders like Transpring to stay at the forefront of industry innovation, setting a higher standard for performance and trust in the rapidly evolving cannabis vape market.

Advanced Quality Control Systems in Cannabis Vape Manufacturing

Strict Raw Material Inspection and Selection

Consistent quality vape products begin with rigorous raw material sourcing. Top manufacturers work with certified growers and supply chain partners to adhere to stringent quality standards. Every batch of cannabis extract undergoes comprehensive testing for potency, pesticides, heavy metals, and microbial contamination.

Precision Extraction and Refining Processes

Extraction techniques such as supercritical CO2 extraction produce pure and stable cannabinoid concentrates. These methods minimize variability in potency and flavor profile. Post-extraction, refining processes such as winterization and decarboxylation are carefully controlled to produce stable concentrates suitable for vape formulations.

State-of-the-Art Formulation and Blending

The formulation process involves precisely blending the extract with carrier agents such as vegetable glycerin (VG), propylene glycol (PG), or natural terpenes. Transpring utilizes an automated blending system with real-time monitoring to maintain precise ratios, ensuring consistent flavor and potency across all batches.

Automated Manufacturing with Real-Time Quality Monitoring

Automation plays a key role in ensuring product consistency. Transpring integrates a robotic filling and sealing system with in-line sensors to monitor parameters such as liquid viscosity, fill volume, and seal integrity. This approach minimizes human error, improves production efficiency, and ensures batch-to-batch consistency.

Innovative Manufacturing Technologies Ensure Consistency

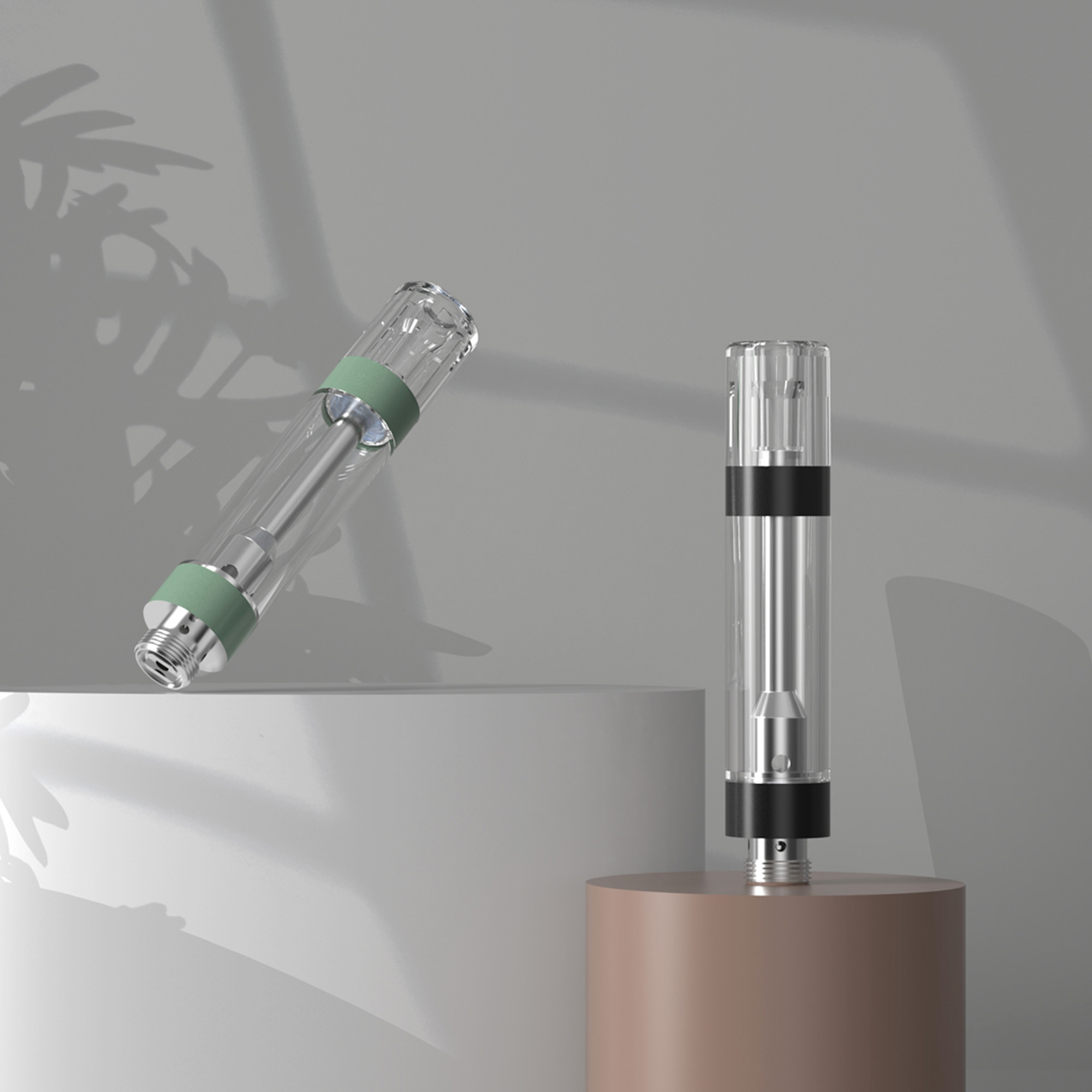

Precision Cartridge Manufacturing

Cartridges are at the heart of vape performance, directly impacting vapor quality and reliability. Leading manufacturers utilize advanced CNC machining and laser welding technologies to achieve precise tolerances and uniform internal dimensions. This sophisticated craftsmanship ensures stable airflow, efficient atomization, and secure battery contact—all key factors in delivering a consistent vape experience. High-precision manufacturing also minimizes the risk of leaks or component failure, thereby enhancing product reliability and consumer trust.

Advanced Battery and Electronics Integration

Battery performance is a key determinant of user satisfaction. To meet this demand, top manufacturers like Transpring seamlessly combine high-quality, safety-certified batteries with intelligent electronic control systems. Automated testing equipment rigorously verifies voltage stability, short-circuit resistance, and thermal management, ensuring each device operates safely under various conditions. The combination of high-quality components and intelligent testing not only extends the device's lifespan but also ensures a consistent and enjoyable vaping experience every time.

Consistent Terpenes and Flavors through Controlled Infusion

Flavor consistency is also crucial to product quality and brand loyalty. To achieve this, terpenes and flavor additives are injected using a precision metering system for accurate dosing and even distribution. Transpring utilizes mass flow controllers and automated dispensing technology to eliminate fluctuations in flavor intensity, ensuring that each cartridge delivers the same taste and aroma from the first puff to the last. This meticulous process preserves the integrity of the formula and strengthens consumer confidence in the brand's reliability.

Strict Regulatory Compliance and Certification Process

Leading manufacturers strictly adhere to ISO standards, Good Manufacturing Practices (GMP), and local regulatory requirements to ensure product safety and reliability. Through regular audits, batch testing, and traceability protocols, every stage of production is monitored, ensuring full transparency and consistent quality for all products. Each production batch has a unique identifier, enabling full traceability from raw materials to final delivery. This system enables rapid recalls when necessary and strengthens consumer trust. Furthermore, independent third-party laboratories verify product potency, safety, and contaminant levels, and certification by reputable organizations demonstrates our commitment to quality and industry leadership.

Continuous Improvement and Innovation in Vape Production

Leading companies like Transpring invest heavily in research and development to enhance product consistency. Their R&D efforts focus on innovative formulations, advanced terpene profiles, novel delivery systems, and next-generation battery technology to ensure reliable performance and consistent quality from batch to batch.

Consumer feedback and field data are integrated into a continuous improvement cycle, enabling manufacturers to monitor real-world performance. Analysis of this data allows for early detection of potential inconsistencies, enabling timely adjustments and corrections before product release, ensuring consistent quality and customer satisfaction.

Sustainable and Responsible Manufacturing Practices

Environmental responsibility is a core principle at Transpring, integrated into every stage of production and rigorous quality assurance. The company prioritizes environmentally friendly sourcing, selecting raw materials that minimize ecological impact while maintaining consistently high standards for product performance. By combining sustainability with precision manufacturing, Transpring ensures that environmental considerations do not compromise the reliability, efficacy, or safety of its products.

In addition, Transpring implements waste reduction strategies and energy-saving processes across all its facilities. From minimizing material waste during production to optimizing energy consumption in manufacturing operations, these practices reduce the company's environmental footprint. By employing sustainable methods without sacrificing quality or consistency, Transpring demonstrates that responsible production methods and high-performance cannabis vape products can go hand in hand, benefiting both the planet and consumers.

Why Choose Transpring as a Cannabis Vape Manufacturer?

Transpring is a leading cannabis vape manufacturer with over 19 years of industry experience. Founded in 2004 and headquartered in Shenzhen, China, Transpring is one of only 600 licensed vape manufacturers in China issued by the State Tobacco Monopoly Administration (STMA). We provide customized cannabis vape solutions for extractors and retailers. We provide expert pre-sales consulting services, supported by teams in China and the US, to help test and determine the specific viscosity, properties, and requirements of each extract to ensure optimal performance.

Transpring boasts a robust R&D department and extensive factory capabilities, capable of meeting OEM and ODM production needs, offering competitive pricing and reliable after-sales support. We are fully committed to excellence, pouring passion and focus into every product we produce. From custom hardware solutions to precision manufacturing and rigorous quality assurance, Transpring ensures high-quality, consistent, and reliable cannabis vape products for customers worldwide.

Conclusion: The Future of Consistent Cannabis Vape Production

Achieving unparalleled consistency in cannabis vape products requires a multi-pronged approach that combines cutting-edge technology, rigorous quality control, strict regulatory compliance, and innovative formulation techniques. Transpring embodies this comprehensive strategy, setting the industry standard and providing reliable, high-quality vape solutions that meet the evolving needs of consumers and regulators.

By continuously improving manufacturing processes, investing in state-of-the-art equipment, and maintaining stringent quality protocols, leading manufacturers will continue to enhance product consistency, safety, and performance—driving the cannabis vape industry toward a future of exceptional consistency and consumer trust.

Contact us today to order your cannabis vape.

Cotton-free vape cartridge with an all-new heating structure.

The REBEL THC disposable represents the pinnacle of cannabis vaping technology, featuring dual ceramic cores for explosive vapor production and superior flavor delivery. This intelligent THC disposable combines smart display functionality with customizable capacity options, delivering an unparalleled cannabis experience for discerning consumers and brand partners worldwide.

A dual airways design cbd disposable vape with an ultra-compact body.

TRANSPRING's first Vape Pen Battery with a digital screen.