CHILL THC Vape Pen Tested and Proven for Today’s Market

As consumers become increasingly sophisticated and discerning about their vaping experience, manufacturers face mounting pressure to deliver hardware that doesn't just work—it must excel across multiple dimensions of performance, reliability, and user satisfaction. In an overcrowded market where countless vape cartridges promise premium experiences but often fall short, one device has emerged from extensive testing with results that demand attention: the CHILL THC vape pen. CHILL doesn’t just look different—it is different. Our no-central-rod, cotton-free ceramic core, and low-temperature atomization approach is designed to meet the demands of a competitive, flavor-driven market. But claims mean nothing without data, which is why CHILL underwent comprehensive testing across the three most critical performance areas: leak prevention, multi-extract compatibility, and real-world user satisfaction.

Before diving into the test results, it's essential to understand the technological innovations that enable CHILL's superior performance. The device features three groundbreaking design elements that work in harmony to deliver an unprecedented vaping experience.

Cotton-Free Ceramic Core Technology

The heart of CHILL's performance lies in its newly designed ceramic core system that completely eliminates cotton wicking materials. Traditional vape cartridges rely on cotton to transport oil from the reservoir to the heating element, but low-quality cotton creates several problems: it can burn at high temperatures, imparts unwanted flavors, and creates inconsistent oil flow that leads to dry hits and hot spots.

CHILL's ceramic core uses advanced science to create uniform heat distribution and consistent oil delivery without any organic materials that can degrade or affect flavor. This cotton-free approach ensures that every draw delivers pure, unadulterated flavor profiles exactly as the extract producer intended.

Dual Airflow Architecture

While most vape cartridges use single-path airflow that creates turbulence and uneven heating, CHILL employs a sophisticated dual airflow system that creates optimal vapor production conditions. This dual-channel design ensures even air distribution across the heating surface, eliminating hot spots that can burn delicate compounds while maintaining consistent vapor density throughout the session.

The dual airflow system also contributes significantly to clog prevention. By maintaining multiple air paths, the system remains functional even if one channel experiences minor blockages, ensuring reliable performance session after session.

Nutun Technology

Perhaps most significantly, CHILL integrates Nutun technology to enable low-temperature vaporization across all extract types. This isn't just about preventing combustion—it's about preserving the full spectrum of compounds that make each extract unique. Terpenes, which provide cannabis's distinctive flavors and contribute to the entourage effect, are highly volatile and easily destroyed by excessive heat.

Nutun technology precisely controls heating curves to maintain optimal vaporization temperatures for different compound types, ensuring that delicate terpenes vaporize efficiently without degradation while still providing complete activation of cannabinoids.

CHILL's development team understood that innovative design means nothing without proven performance. The testing protocol addressed the three most common pain points cannabis consumers experience with vape hardware: leakage, extract compatibility, and overall user satisfaction.

Test 1: Leakage Resistance

Leakage represents perhaps the most frustrating failure mode in cannabis vaping. Beyond the obvious waste of expensive extracts, leaks create a mess, reduce potency, and often render cartridges completely unusable. CHILL underwent extensive pressure testing under various conditions to verify its leak-proof design.

The testing protocol subjected CHILL devices to both inverted and upright positions over three consecutive days, simulating real-world storage conditions that often trigger leakage in conventional cartridges. The results were unambiguous: zero leakage across all test conditions and positions.

This performance stems directly from CHILL's post-free design and precision engineering. By eliminating the central post that creates potential leak paths in traditional cartridges and employing advanced sealing technologies, CHILL maintains perfect containment regardless of orientation or storage conditions.

Test 2: User Trials with Rosin, Resin, and Distillate

Real-world feedback matters as much as lab results, which is why we assembled multiple groups of 10 participants each, focusing on three oil types known for their unique demands:

Rosin – Known for its solventless purity and terpene richness, but also for its thicker consistency that challenges many vape devices.

Resin – Typically more fluid than rosin, but still requires precise temperature management to protect flavor compounds.

Distillate – Highly refined, with consistent viscosity, but demands stable heating for smooth, repeatable draws.

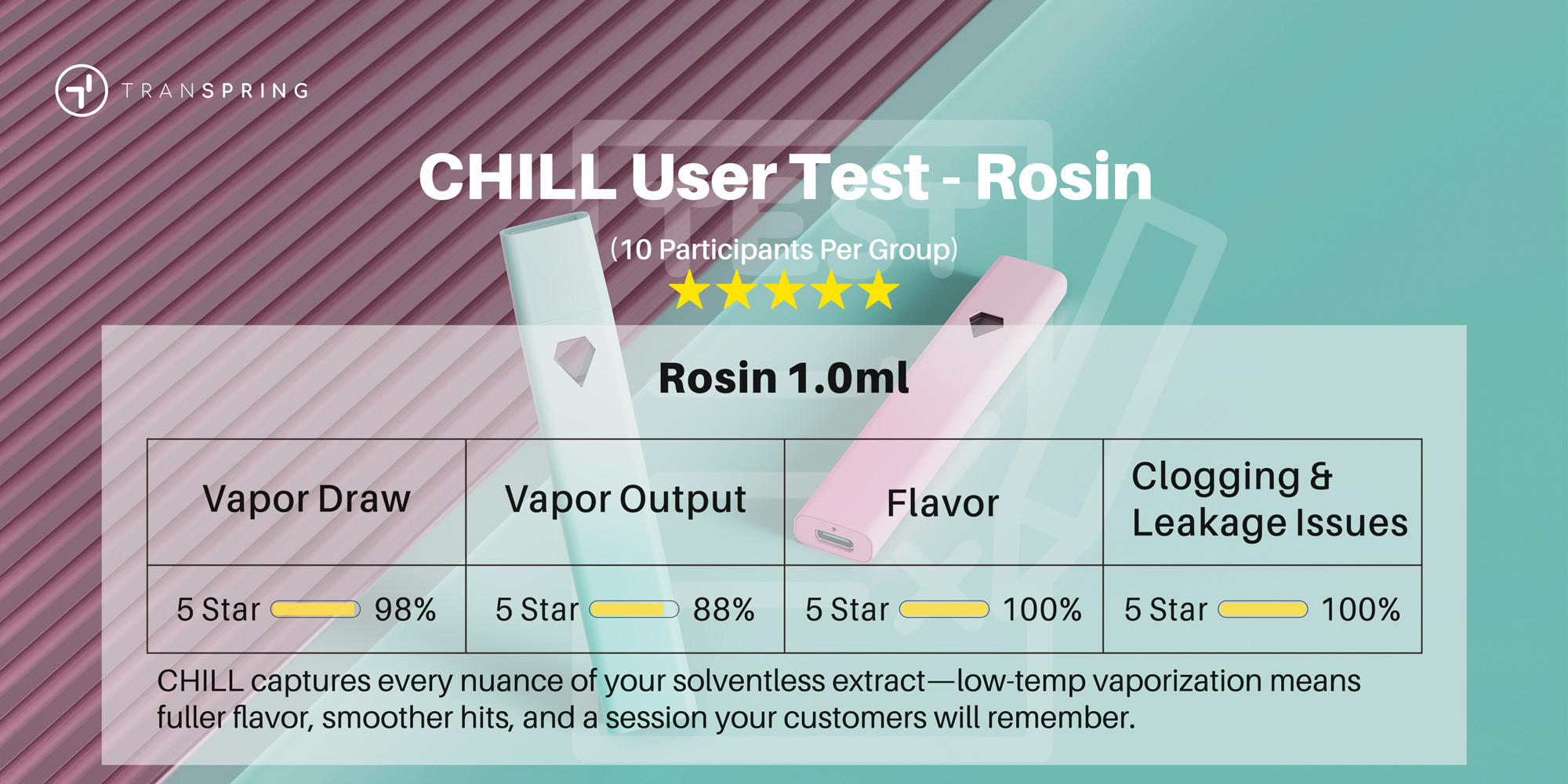

Each group evaluated four critical performance factors: vapor draw, vapor output, flavor, and clogging/leakage issues.

Rosin Test Highlights

Vapor Draw: 98% of participants rated 5 stars

Vapor Output: 88% 5-star rating

Flavor: 100% 5-star rating

Clogging & Leakage: 100% 5-star rating

This performance is significant because rosin can be notoriously difficult to vaporize evenly without overheating or clogging. CHILL’s low-temp ceramic heating core excelled at unlocking the full flavor spectrum without burning delicate terpenes, while dual airflow pathways ensured smooth, consistent inhalation.

Resin Test Highlights

In resin tests, CHILL maintained exceptional stability, providing rich, full-bodied vapor without spitback or thinning issues. Flavor consistency was highlighted as a major win by participants, thanks to Nutun™ temperature modulation that adjusts power in real time.

Distillate Test Highlights

Distillate’s predictable viscosity might make it seem easy to vaporize, but in reality, it can expose flaws in heating control—overheating results in harshness, underheating causes weak vapor. CHILL’s controlled power curve ensured even, repeatable hits with clean flavor from start to finish.

The vaping experience is shaped by more than just the oil inside—it’s the hardware that delivers the flavor, texture, and satisfaction customers remember. CHILL’s outstanding test results, across both lab and user environments, prove that thoughtful engineering pays off.

By combining a cotton-free ceramic core, dual airflow channels, and NUTUN™ low-temperature control inside a post-free leak-resistant body, CHILL stands ready to meet the demands of modern cannabis consumers—and the brands that serve them.

For companies seeking an all-in-one solution that excels with rosin, resin, and distillate alike, CHILL offers a tested, proven path to better vaping experiences.